A mechanism is defined as a design with one or more moving parts. Inventor provides numerous tools to assist you in creating and evaluating a mechanical design.

Use sketch blocks in a 2D part sketch to create a schematic layout of your mechanism. Create flexible, nested blocks and apply sketch constraints to define subassembly kinematics. Derive sketch blocks into component files and create other features to develop your 3D models. The components remain associated to their corresponding blocks and update to reflect any changes in block shape.

Tools to evaluate mechanisms

Use the following tools to evaluate a mechanism in the 3D environment:

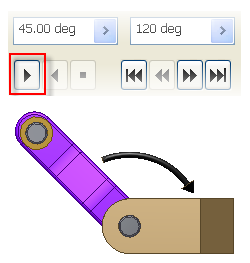

- Animate an assembly constraint and enable collision detection to determine the exact point of contact. For example, animate an angular constraint to evaluate the range of motion before contact occurs.

- Create a Contact Set and add members as required to simulate physical contact between components and to determine the range of motion.

- Use Positional representations to save a mechanism in various states such as maximum and minimum extension.

- Use Inventor Studio to animate simultaneous or sequential movement.

- Use the Dynamic Simulation Environment to calculate displacements, velocities, accelerations, and reaction forces without the cost of a physical prototype.

- Use the Stress Analysis Environment to conduct structural static and modal stress analysis studies on the digital prototype.

.gif)

0 comments:

Post a Comment